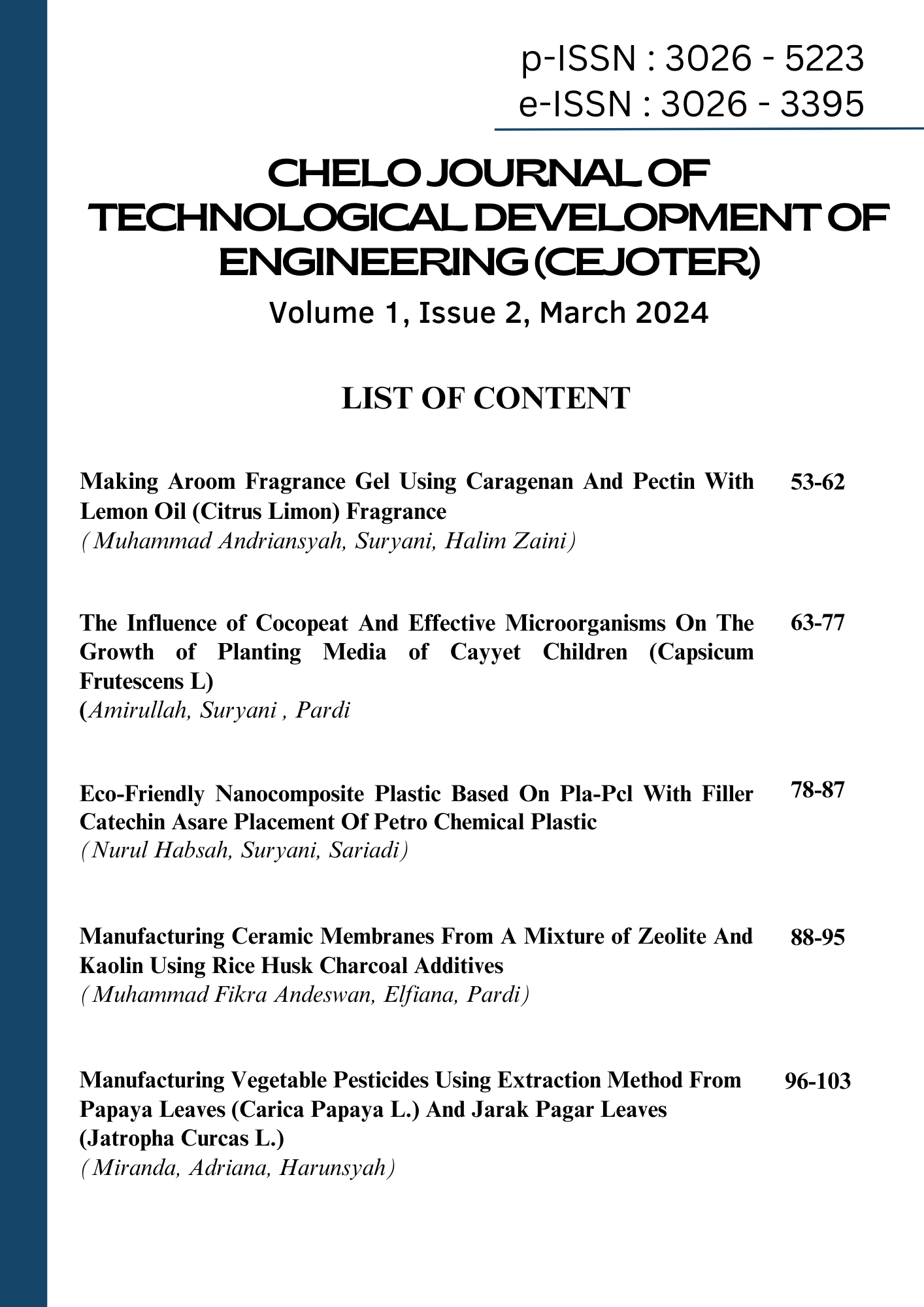

MANUFACTURING CERAMIC MEMBRANES FROM A MIXTURE OF ZEOLITE AND KAOLIN USING RICE HUSK CHARCOAL ADDITIVES

DOI:

https://doi.org/10.61972/cejoter.v1i2.24Keywords:

Ceramic Membrane, Sintering, Swamp Water, Water FilterAbstract

One of the easy-to-apply ways to solve water purification problems is by making filters. Currently, clean water treatment with membrane technology is a very promising treatment process with excellent quality and suitable for many advantages. The purpose of this study is to determine the effect of variations in the composition of materials, namely zeolite, clay, and rice husk charcoal. At the stage of making membranes, zeolite and kaolin variations were carried out. For zeolite: kaolin variations are 75: 10, 55 : 25, 35 : 35, 25 : 55, and 10: The results of the study obtained quality that meets the SNI 01-3553-2006 requirements such as an average pH of 7.48, an average TDS of 98 mg/L, and an average turbidity of 0.914 NTU. The best comparison is 35% Zeolite: 35% Clay with the addition of 15% rice husk charcoal.