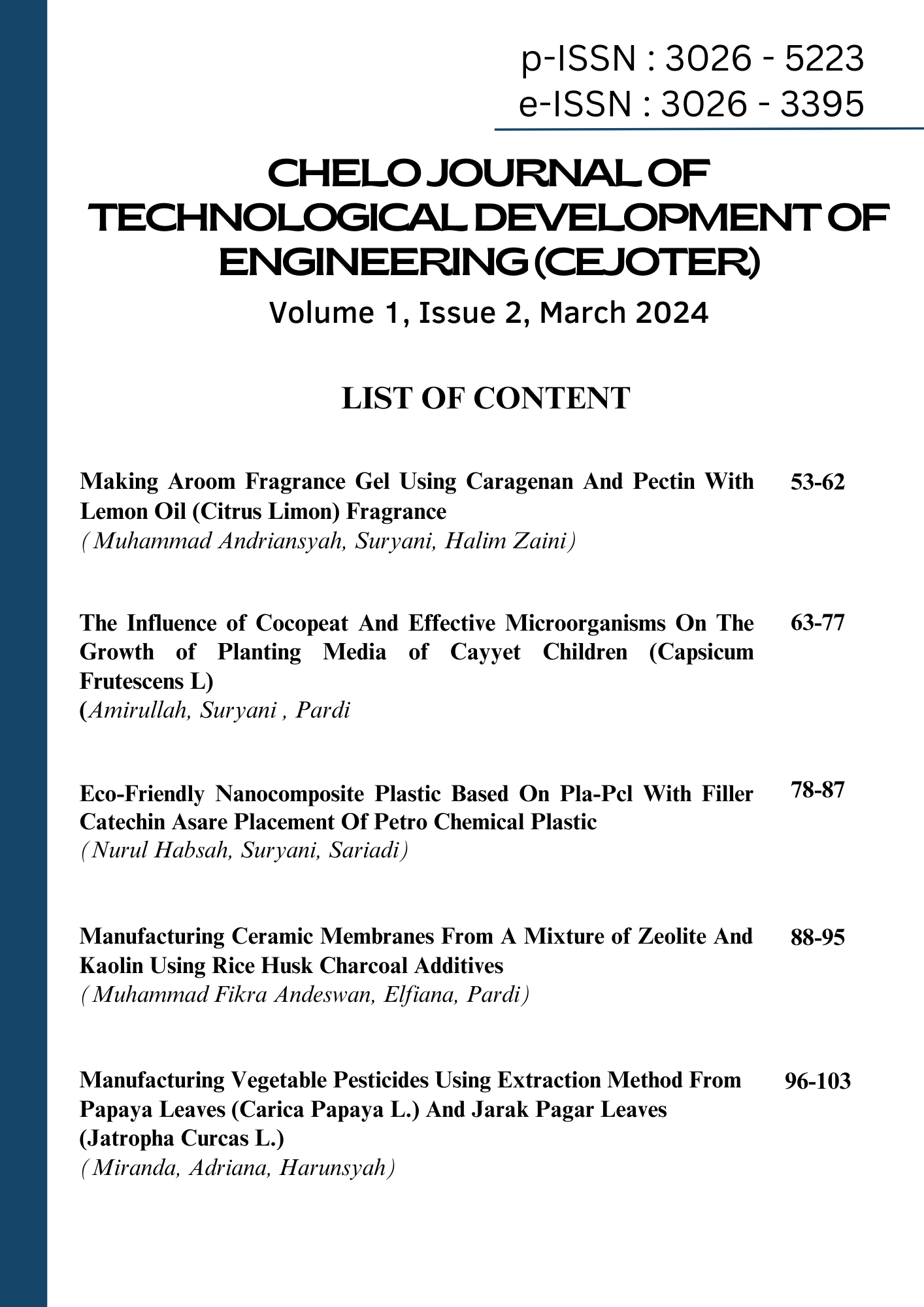

ECO-FRIENDLY NANOCOMPOSITE PLASTIC BASED ON PLA-PCL WITH FILLERCATECHINASAREPLACEMENTOFPETROCHEMICALPLASTIC

DOI:

https://doi.org/10.61972/cejoter.v1i2.23Keywords:

Poly Lactid Acid (PLA), Polycaprolactone (PCl), Catechin, FTIR, TGA, BiodegradableAbstract

The widespread use of plastics from petrochemical polymer materials has caused major problems for the environment, the solution requires quality biocomposites as replacement raw materials. Innovation combines Polylactid Acid (PLA) and Polycaprolactone (PCL) biopolymers with catechin filler using a mixing and melting method to get the best mixing of PLA-PCL and catechin filler using a mixing and melting method to get the best PLA-PCL mixing. PCL is combined with catechin as a filler. The composition of the PLA-PCL matrix used in this research is 2:8; 3:7 ; 5:5 ; 7:3 and 8:2, with variations in adding 0.2g of catesin filler; 0.3 grams; 0.4 grams; 0.5g and 0.6g. The melting temperature is 180oC with a holding time of 20 minutes in the sample formation process on the ASTM D-638 Type I specimen which produces plastic rods/bones. Based on the results of tensile strength testing, FTIR analysis, TGA analysis and biodegradable analysis, the maximum tensile strength obtained in the PLA-PCL 8:2 composite with the addition of 0.6g filler was 46.73 Mpa. The FTIR test shows that there are C – H and C=O groups and no new functional groups are formed

Additional Files

Published

Issue

Section

License

Copyright (c) 2024 Chelo Journal of Technological Development of Engineering (CEJOTER)

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.