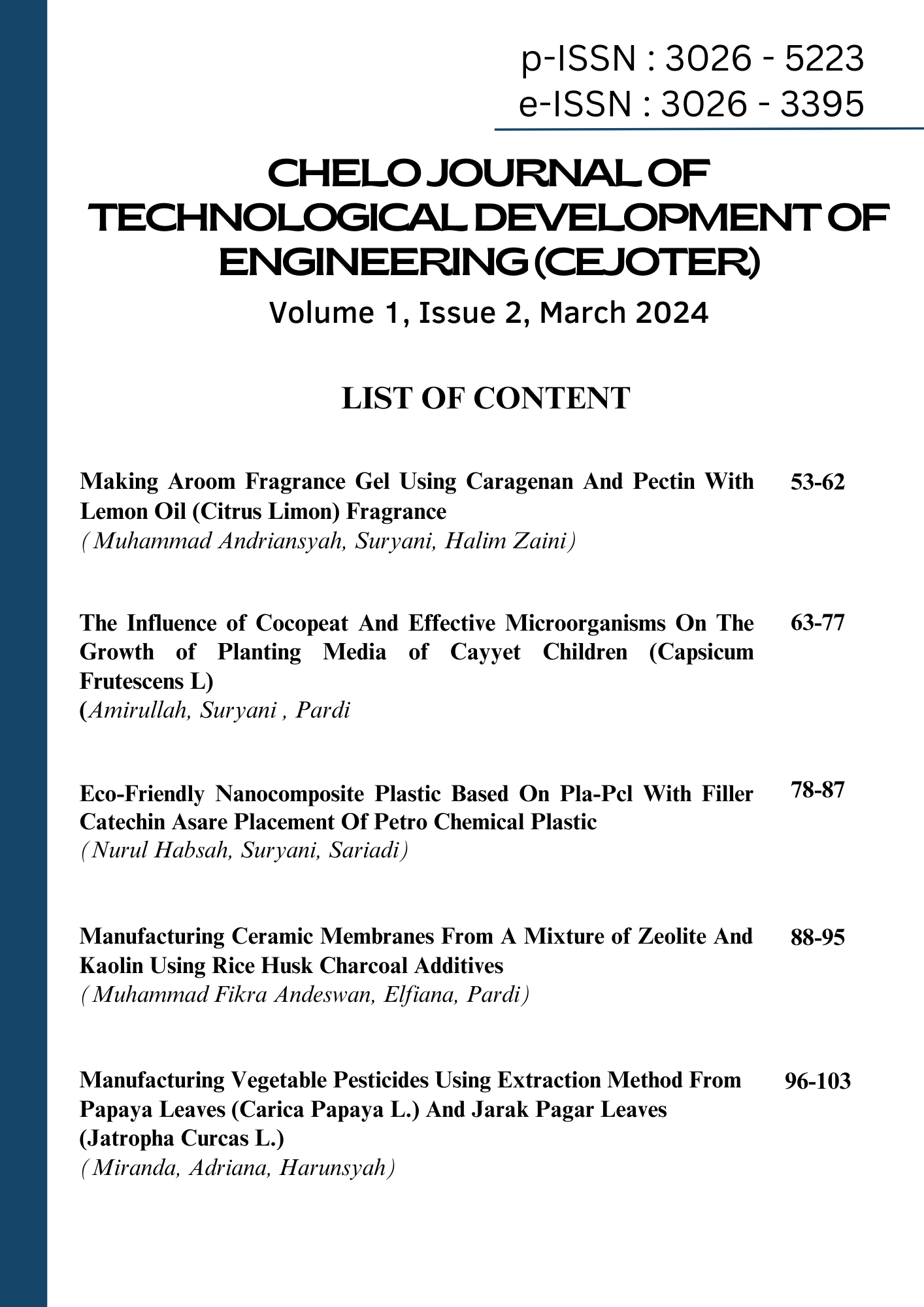

INVESTIGATION OF POLYURETHANE PRIMER COATING PAINT BASED ON LOCAL PALM OIL WITH ANTIMICROBIAL AND ANTICORROTION AGENT FORMULA BENTONITE-CHITOSAN

DOI:

https://doi.org/10.61972/cejoter.v1i2.26Keywords:

Biodegradable, Paint, Polyurethane, Bentonite, ChitosanAbstract

Paint is a product that is really needed to coat iron or steel materials such as industrial pipes, medical equipment, and others. Problems that are currently felt by the public and industry regarding paint products include paint peeling on the coated material. The innovation of adding bentonite-chitosan filler is able to improve the physical properties of coating paint. The sample formulation used was the addition of 2%, 4%, 6%, 8% w/w bentonite chitosan filler.The results of the Fourier Transform Infrared (FT-IR) test show that there are NH, CH, C=O functional groups.In the Thermogravimetric Analysis (TGA) test, the sample experienced single decomposition and showed the best results for the Polyurethane/Bentonite/Chitosan 8:8 % w/w sample where the sample began to degrade at a temperature of 416.85(oC). SEM testshows that the chitosan chains are well dispersed into the bentonite interlayer. The results of the bacterial test showed the best results on the samplesPolyurethane/Bentonite/Chitosan 8:8 % w/w has the widest zone of inhibition with a value of 6.9 mm for E.Coli bacteria. Corrosion tests show that the addition of bentonite and chitosan affects the corrosion rate, the greater the composition of bentonite and chitosan can reduce the corrosion rate. The sample with a Polyurethane/Bentonite/Chitosan composition of 8:8 % w/w was the best sample where the sample experienced the smallest corrosion rate, namely 5.08 mpy.

Additional Files

Published

Issue

Section

License

Copyright (c) 2024 Rihayat Teuku, Sariadi, Muhammad Yunus, Alfian Putra, Januar Parlaungan Siregar, Tezara Cionita, Harunsyah, Irwan, Isra Adelya Izzati, Sabila Yasara Sa, Nurhanifa, Adi Saputra Ismy

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.